An

idea for a house built through assembling and wrapping the basic needs

of dwelling, such as doors, windows, cooking and sanitary functions, as

a series of ready-made wall-cum-furniture sections. The individual

house can be laid out as a kit of parts according to the occupant's

preference and site constraints. In multiple, the homes can be stacked

into mini-towers using an external load-bearing frame and circulation.

Shortlisted in the BTI Home Competition, 2012.

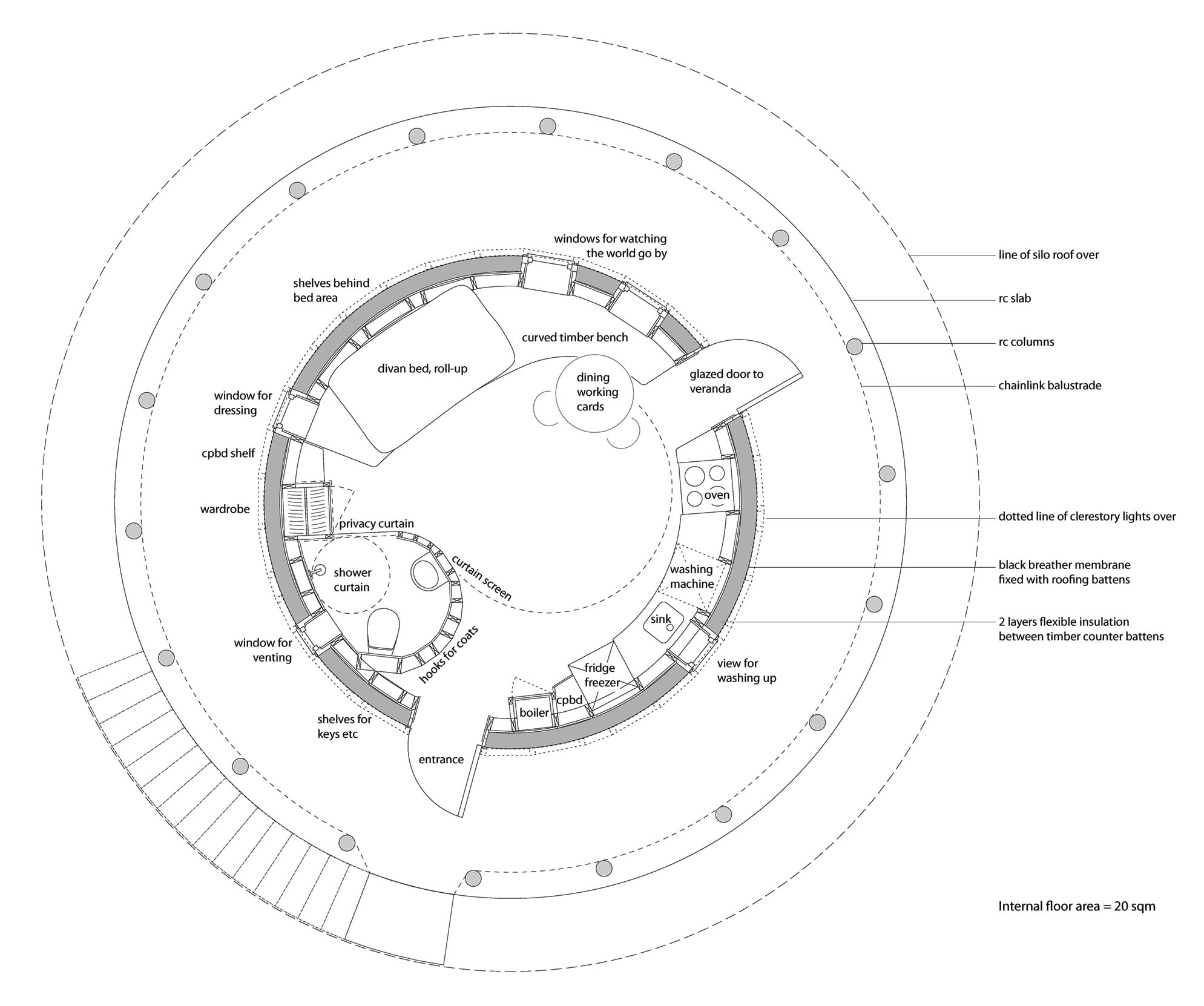

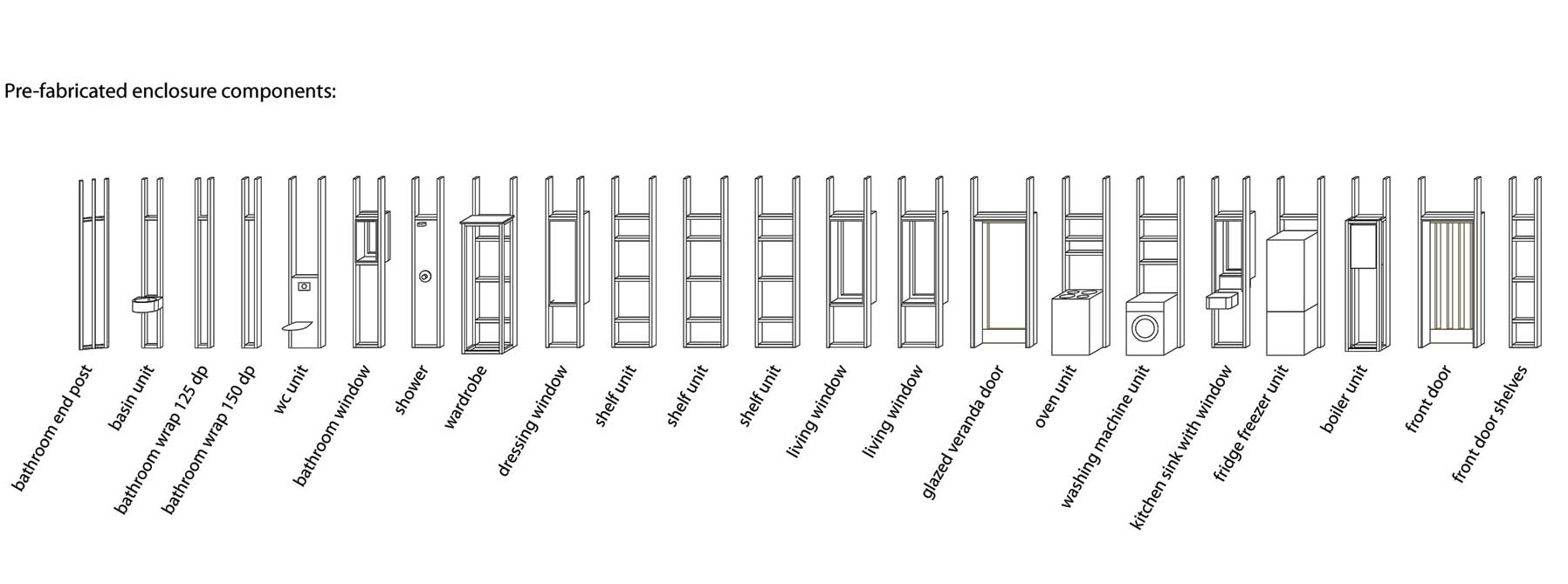

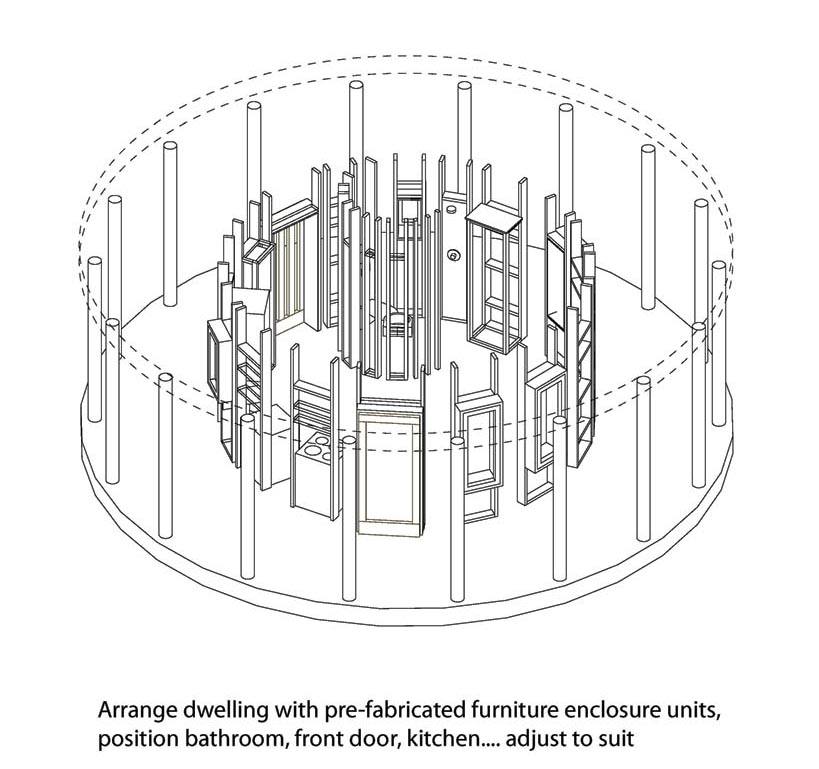

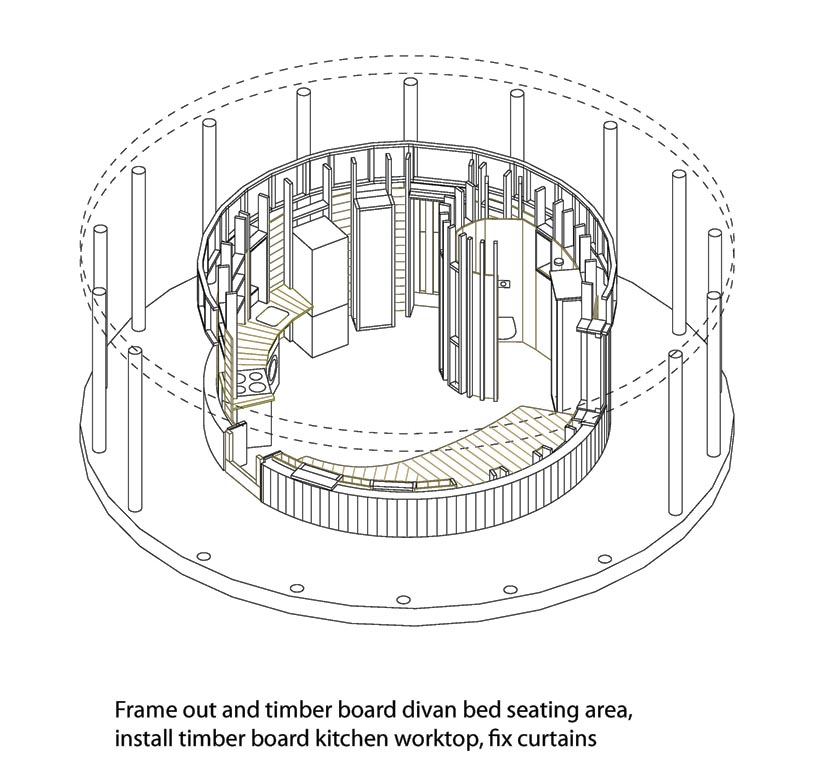

HOME WRAP is a furniture-component house for a single dweller that uses a flexible enclosure strategy. The enclosure consists of a series of pre-fabricated furniture components generated from the core activities of dwelling: cooking, eating, sleeping, washing, storing and displaying. These are arranged to suit the dweller & then fixed and wrapped with insulated cladding.

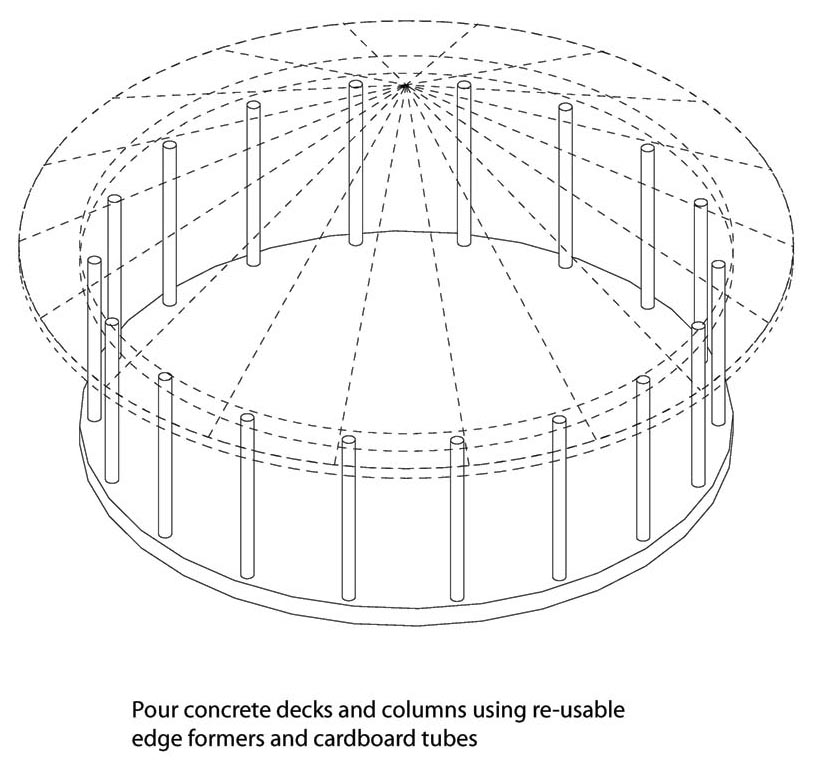

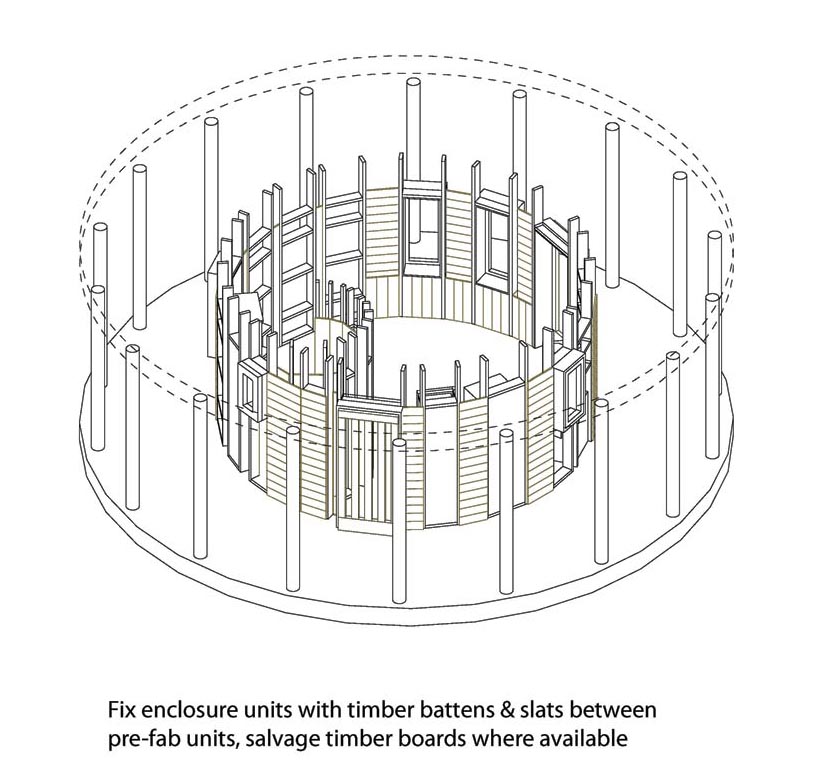

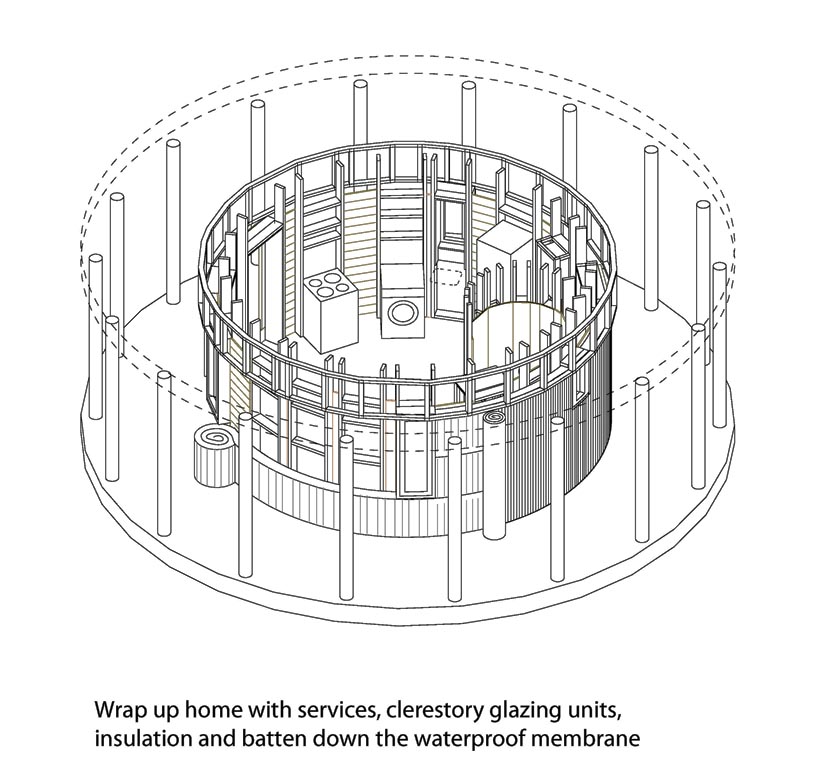

The base plate for the construction is a round reinforced concrete floor deck with a ring of concrete columns for the support of roofing or upper storeys. The living space proper is created by the arrangement of the prefabricated furniture components: shelves, wardrobe, bathroom and kitchen units and external doors & windows. With the components in place, the interstices are filled with timber cladding, and the entire structure is wrapped with insulation material and a breather membrane to form the outer skin.

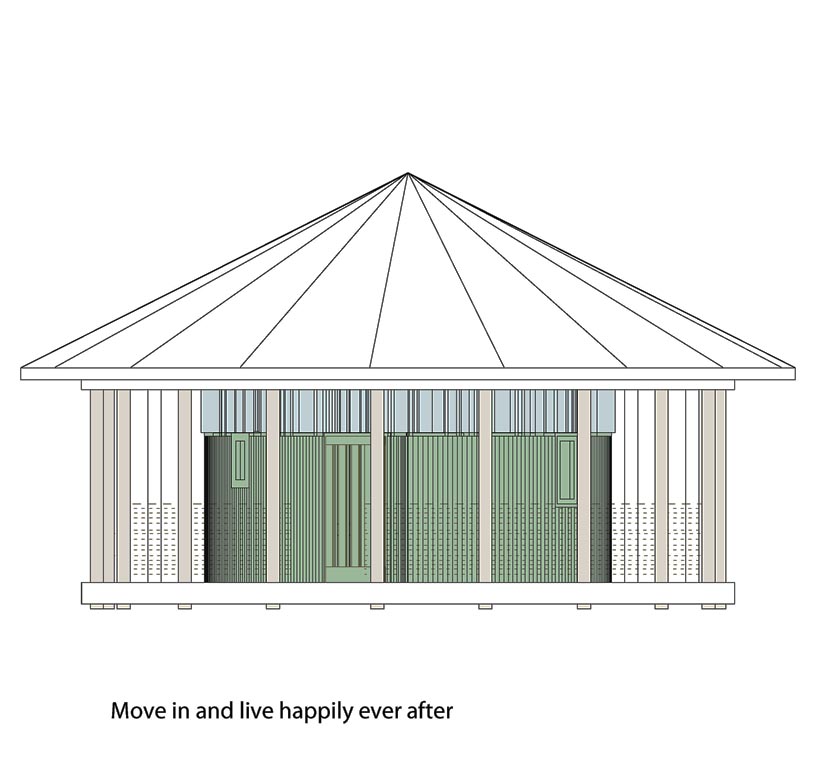

Completed with a divan bed and seating, the furniture units thus wrap an open central area that creates a sense of spaciousness on a floor area of just 20sqm. The external space consists of a circular verandah 1.7m deep – to be used for plants, growing vegetables, hanging out laundry, the storage of bins, bicycles etc – that is enclosed with a fence of chainlink mesh, allowing vine plants to grow round.

The choice of materials was determined by considerations of economy and ease of use. All components are standard, and some can be sourced from recycled material (timber, boarding) while others are suitable for later recycling (concrete, timber). They consist of reinforced concrete, an insulated silo roof, timber posts, slats and cladding, flexible insulation material and black breather membrane fixed with timber roofing battens.

HOME WRAP stands alone but can also be stacked in multi-storey configurations that are accessed by a silo staircase. Externally, it exhibits a strong graphic that is based on the choice of materials: a dark central drum, accentuated by the ring of glass that forms the clerestory, which contrasts with the lighter concrete slabs and columns and with the aluminium roof. The exterior thus displays a sense of strength, based on the industrial quality of its materials while the interior has a more domestic, comfortable feel that is evoked by the timber components and the abundance of light from the clerestory windows.

HOME WRAP is a flexible system of providing individualised dwelling that is suitable for a variety of sites and climates. The chosen site for this project is an unused brownfield site in central Chicago, IL, one the corner of East Lake Street and North Stetson Avenue. Some of the city’s foremost hotels and office buildings, like the high-rise structures of 205-225 North Michigan Avenue and Mies van der Rohe’s Two Illinois Centre (1973) back onto the site that is otherwise flanked by Chicago’s riverside double-decker road system. In particular the repetitive stacking and grouping of the tiny HOME WRAPS forms a striking answer to the overwhelming monumentality of the surrounding towers.

|

|

|

|

|

|